Products

Contact us

Tel:0769-85609008

Fax:0769-85780118

E-mail:limited@shentongboli.com

Add:No.1, First Ring Road, Huaxia Industrial Zone, Langxia Village, Qiaotou Town, Dongguan City

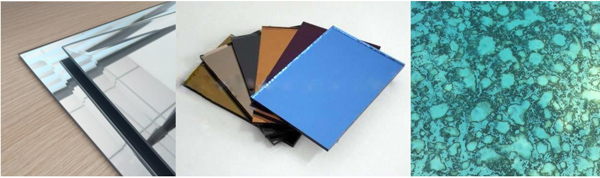

Various lenses

mirror

The mirror is a silver-plated glass on the bottom of the glass, also known as a glass mirror, mirror glass, etc. The silver mirror is a silver-plated mirror made of ordinary white glass, and the mirror is called a gray mirror, such as a gray mirror, a tea mirror, a gold mirror. Pink mirrors, blue mirrors, black mirrors, etc., among which the most common applications of silver mirrors are most common. Mirrors are widely used in furniture, crafts, decoration, bathroom mirrors, make-up mirrors, optical mirrors, and car rearview mirrors. Common mirror

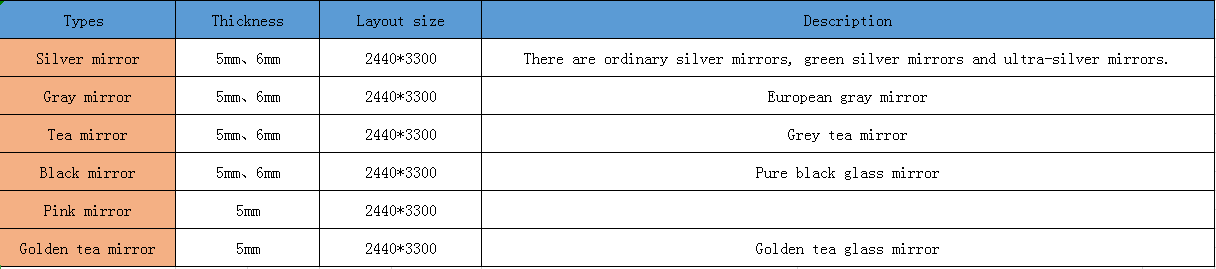

Our company's standing stock mirrors have the following types:

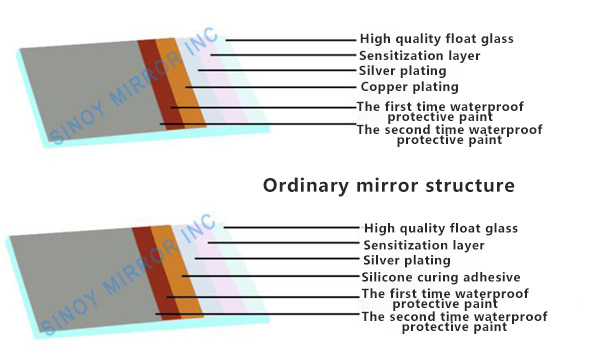

Mirror production process

The mirror is chemically coated on the glass surface first to form a reflective film, then a copper protective film, and then a first layer of protective lacquer, and a second layer of protective film. The whole process of production is completed in one time using a fully automatic production line. The length of the production line is about 160 meters. It is sent from the glass to the upper end, polished and polished → sensitized → silver plated → copper plated → blown dry → preheated bake → primed → Primer drying → topcoat → topcoat drying → air drying and cooling → mirror cleaning → blow drying → spray code → quality inspection packaging Fully automated one-time completion of silver-plated glass mirror production, the main processes are as follows: sensitization: before silver plating Tin salt sensitization treatment (palladium salt treatment, suitable for copper-free mirror production). Silver plating: The silver nitrate reduction film is used to produce a reflective silver film. Copper plating: chemically displaced to form a solid copper film to protect the reflective layer (no copper mirror without this process, changed to silicone curing). Curing: two layers of primer, protective primer: waterproof, acid and alkali resistant protective paint; protective topcoat: waterproof and hard low lead (lead-free) protective paint.

Ordinary mirror and environmental mirror

According to the mirror protective layer containing a copper-free protective layer, the mirror is divided into a common mirror and a green mirror (also called a copper-free mirror). The environmental protection mirror effectively overcomes the environmental pollution caused by the replacement reaction of copper sulphate powder in the traditional silver plating process. Instead of a copper-plated chemical replacement process, a passivation process (ie, spraying a silicone curing agent, acting as a copper layer with a silver-plated glass mirror) is used to spray an acid-alkali-friendly environmentally-friendly imported primer, a high-hardness waterproof imported topcoat, and a green mirror. Features: high reflectivity, corrosion resistance (edge corrosion resistance is three times that of ordinary silver mirror), waterproof, lead-free, copper-free.

Antique mirror

Antique Mirror is also a kind of mirror, but it is not an antique mirror in the traditional sense, but the latest popular decorative mirror in the world. It is different from the aluminum mirror and silver mirror used in our daily life. It has undergone special oxidation treatment, and forms various shapes and colors on the mirror. It has an ancient charm and can create a feeling of passing through time and space. As an area of glass decoration, antique mirrors add a retro, elegant and luxurious atmosphere to the interior decoration. They are favored by the retro-style decoration style and are widely used in high-end decoration such as wall, background and bathroom. It is very popular in Europe, the United States, Japan, and South Asia. There are many kinds of antique mirrors, and different mirror factories have their own specific patterns.

Mirror black side and speckled reason

The main reason for the black edge of the mirror is that when the glass lens is subjected to edging, the silver layer in the section of the section is exposed to the air and is oxidized by the electrolyte (acid, alkali, salt, etc.) to form an oxide and black. Thus, the black side is formed, and the silverware will change color like a long time. The silver plating on the back side of the mirror will also oxidize and darken to form spots, similar to the color of the silverware in the ancient costume film. What happens in life will make the mirror edge black? The trace acid gas in the air includes some carbon dioxide, sulfur dioxide; a daily chemical containing surfactant, metal ion, alkaline or acidic; construction site or other decoration materials Various pollutants, such as silicone rubber (glass glue), unclean water, humid air, and even human sweat (salt).

In order to make the mirror have no black edge problem, in addition to using the environmental protection mirror as much as possible, it is also possible to use the edge-sealing agent method to seal the cross-section cut of the mirror-finished edge with an edge-sealing agent, and block the contact with the air to prevent it. Or slow down the oxidation reaction. In addition, the mirror should not be stacked with alkaline and acidic materials to avoid storage in a humid environment.